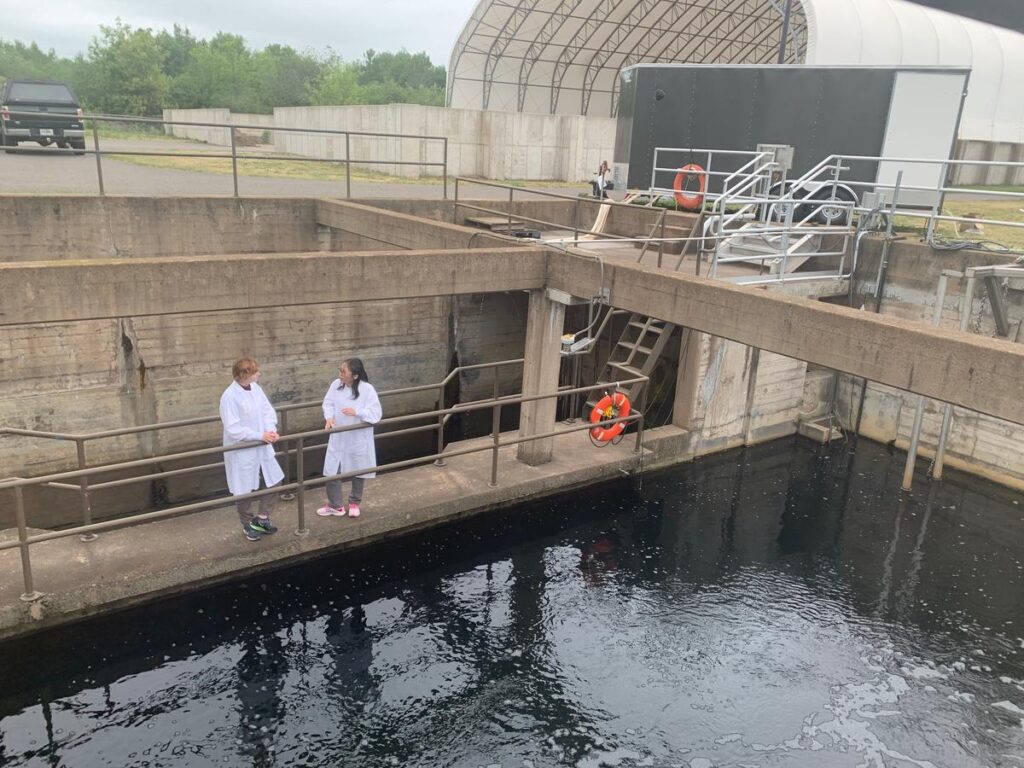

New technology is being tested that could someday remove sulfate from waters where it can hurt manoomin, or wild rice. A technique being worked on by the University of Minnesota’s Natural Resources Research Institute (NRRI) seeks to use microbes and minerals to capture sulfate. It is currently being tested on discharge from wastewater treatment plants, a significant source, along with mines.

MPR News reports that the method converts the salty chemical, which is not poisonous but creates a chain reaction in bottom sediments that reduces wild rice growth, to a stable compound and binds it to other minerals so it can be removed as a sludge, which can be disposed of on land.

“What we’re trying to deal with here is show that whatever is coming out of the plant, we can reduce the sulfate enough so that when the effluent from the plant goes into the environment, it doesn’t pose a significant impact on sulfate concentration in the region,” said Rolf Weberg, NRRI executive director.

Currently, the only option available to treatment plants, mines, and other sources of sulfate currently is reverse osmosis, an energy-intensive and expensive process. Questions remain about the method’s possible costs if it proves feasible, but a lead researcher says the new method holds promise.

“Operation costs are relatively low and the system is easily adapted for equipment in place at a plant or facility,” said Dr. Mei Cai, NRRI environmental engineer.

Minnesota is the only state in the country with a water quality standard to protect wild rice. Manoomin is an important food source and cultural resource, particularly for Anishinabe people, and it has already been eliminated from many Minnesota waters by pollution, dams, and other activities. The state has not enforced the standard since its creation in the 1970s, but the federal Environmental Protection has ordered the state to do so under the Clean Water Act.

To help municipalities and mining companies, the NRRI has been working to develop such methods for the past few years. Its new method has already managed to reduce sulfate in sample wastewater discharge from 80 to 90 ppm to at or below the state’s 10 ppm standard.

Another northern Minnesota enterprise is also seeking to develop a solution to the sulfate problem. Clearwater BioLogic of Babbitt is working on a device that could float in mine lakes and remove sulfate. Founder Jeff Hanson says it uses natural bacteria to convert sulfate to sulfur, which can in turn be removed. He also says the company has identified another partner that could use the byproduct for another purpose, reducing waste. Details are few, but Hanson told MPR News in 2018 that operating costs would be one-tenth of reverse osmosis.

Environmental advocates caution that untested technology should not be used to claim proposed mines will be able to operate without polluting water.

“That is the biggest concern we have, is that if people start saying, ‘Well, maybe at some point in the future, we’ll be able to remediate it,’ that might be an excuse for failing to use the technologies, whether it’s the liners or the nanofiltration that are necessary right now, to prevent more pollution,” Paula Maccabee of WaterLegacy told MPR News.

The NRRI says it hopes to have its technology available within a few years. The researchers will need to partner with a municipality to construct a pilot treatment plant first. It is also developing methods to use peat to remove sulfate. Clearwater BioLogic is marketing its technology now.

More information:

- Northern Minnesota researchers close in on sulfate pollution solution – MPR News

- NRRI develops portfolio of solutions to address sulfate challenges – Natural Resources Research Institute

- Clearwater BioLogic – System Details