A mobile trailer packed with scientific equipment stands near the shores of Birch Lake, about 20 miles south of Ely. While he’s not the only one working on solutions, Jeff Hanson’s lab may offer a method to remove sulfate pollution from watersheds flowing into the Boundary Waters Canoe Area Wilderness. Sulfate continues to plague these pristine lakes and river systems. It harms humans and contributes to toxic mercury levels in fish. Researchers report that taconite mining complexes discharge wastewater, which leaches sulfates into downstream waters.

Filtering sulfate pollution at the source

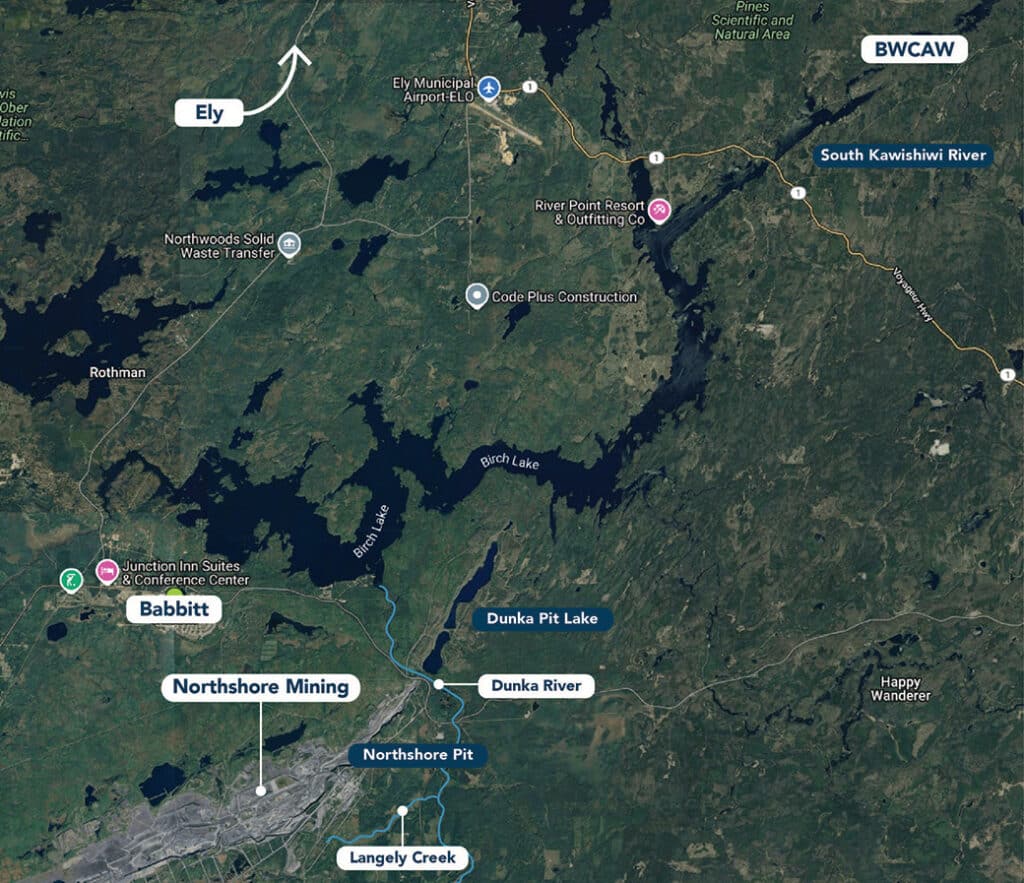

Sulfate pollution is increasing in northern Minnesota waters. Researchers cite taconite mining activities as the source of the problem. However, a team of scientists, engineers, and researchers say they have a straightforward and economical solution to remove sulfates from mine waste before it leaves the mine complex. Jeff Hanson, owner-partner of Clearwater BioLogic based in Babbitt, MN, has spent the past decade developing a technology that he says “follows nature’s lead” in removing sulfate pollution from water. Hanson, who grew up in the Iron Range, now lives along the shore of Birch Lake. Northshore Mine, one of the taconite complexes at the center of the issue, sits about ten minutes southeast of his place. An Ohio-based company, Cleveland-Cliffs, owns and operates the taconite facility.

He has clean water on his mind when we meet to see his mobile lab sitting in his driveway. When we walk in, I see a straightforward system of tanks and tubes that he says removes sulfate pollution from water effectively. Many people view his solution as positive, but some, he says, see his work as a threat to mining.

He doesn’t oppose iron mining, though. “It’s what brought me to northern Minnesota,” he says. But later, as he looks out the large picture window of his home, it’s clear he’s passionate about protecting the water that eventually flows north into the Boundary Waters Canoe Area Wilderness (BWCAW) and beyond.

About a decade ago, he began developing a treatment system to clean up sulfate pollution. When I view the scaled-down version in his mobile lab, Jeff explains the process.

Steps to removal

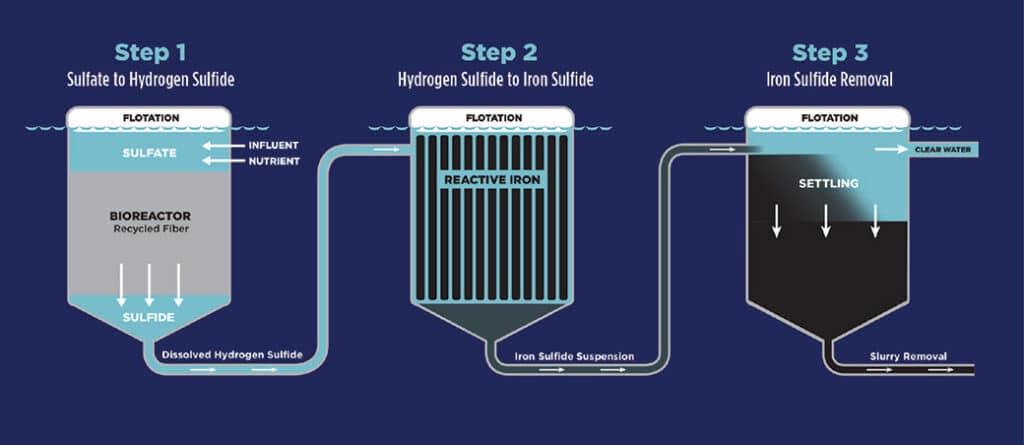

Water from Spring Mine Creek, which runs near the defunct LTV Steel Mining Company, sits in a large plastic tank outside his mobile lab. This tank pumps sulfate-contaminated water into another tank, or “bioreactor,” inside the lab. Loose fibers from post-consumer polypropylene carpet line the bioreactor. They provide a cheap, effective surface for growing sulfate-reducing bacteria.

A small bag outside the tank holds a liquid biodegradable solution that feeds the bacteria. These bacteria breathe by using the oxygen bound in sulfate molecules, which allows them to break down the sulfate. Then, moving through a bioreactor treatment, the process converts sulfate into hydrogen sulfide.

Water then flows into a third tank, where direct-reduced iron pellets (DRI) react with hydrogen sulfide to form iron sulfide. The iron sulfide settles and forms a black slurry. Hanson extracts the slurry and points out an added benefit: the iron sulfide is marketable and useful in several applications. The process uses no chemicals and generates no waste upon completion.

Direct reduced iron or DRI starts as iron ore, usually in pellet or lump form. A reduction furnace removes the oxygen without melting the ore, producing pure, porous iron known as DRI. It works well in sulfate remediation because it reacts with hydrogen sulfide, binding the sulfur into a solid. DRI is also electrically conductive and non-polluting. Some manufacturers have started producing it in Minnesota or plan to do so. Hanson feels excited about the potential for a local supply, which would reduce costs by avoiding the need to ship DRI from elsewhere.

Removing toxins before they head downstream

The Minnesota Pollution Control Agency (MPCA) currently enforces a sulfate standard of 10 mg/L (milligrams per liter), a limit it set in 1973 to protect wild rice waters. In addition, the state set a standard of 600 mg/L of sulfate for industrial use, including mining. However, reports show that sulfate levels in mine pit lakes often exceed that limit. The Environmental Protection Agency sets a lower standard of 250 mg/L for drinking water.

In their testing, Hanson’s team consistently reduced sulfate levels to below 3 mg/L. He believes their three-step process, when deployed, can treat water and remove sulfate from mine pit lakes or tailings basin ponds before the water flows downstream.

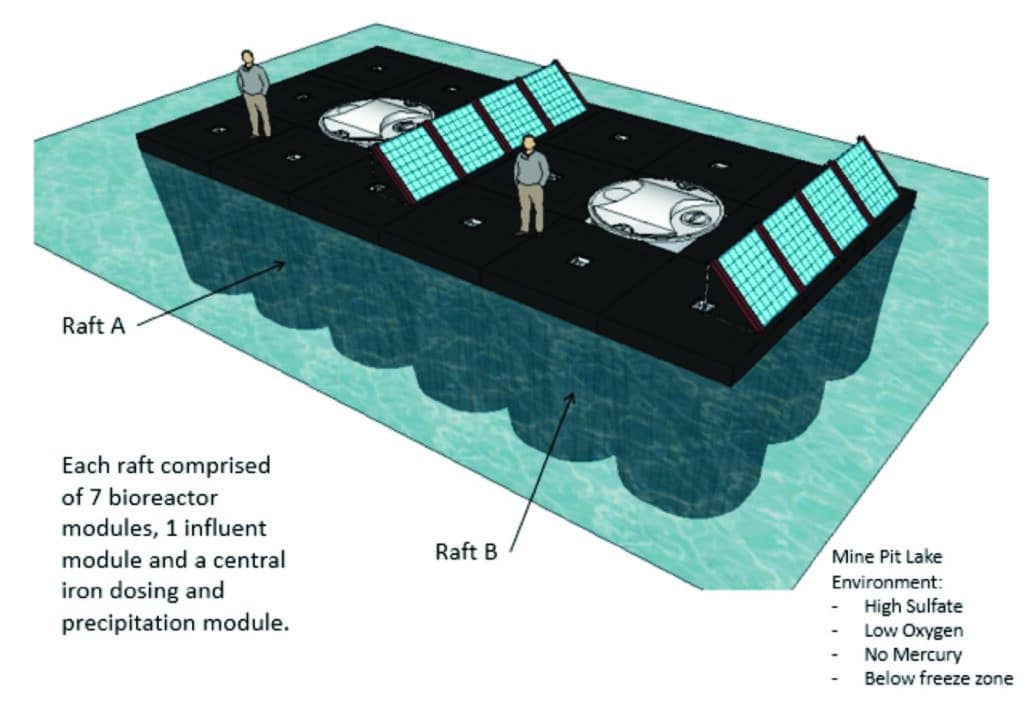

Engineers have taken and replicated the mobile lab’s sulfate clean-up system in the field on floating modular platforms. The bioreactor cells form “islands” that host sulfate-reducing bacteria in containment vessels. The system can scale up or down to meet sulfate removal needs.

Starting in 2016, Hanson, in collaboration with the University of Minnesota, tested the system at a mine pit controlled by PolyMet and Cleveland Cliffs over five seasons, including winter. That pit contained water with sulfate levels measuring 1,100 mg/L. The floating bioreactor achieved over 99% sulfate reduction in winter testing, sometimes even 100%. Lab testing also produced similar results.

Various industry partners funded and supported the study. These included the Iron Range Resources and Rehabilitation Board, the Natural Resources Research Institute, the University of Minnesota, the East Range Joint Powers Board, Cleveland-Cliffs, and PolyMet. They’ve continued to show interest as testing by Clearwater BioLogic continues.

Sulfate leads to high levels of mercury in fish

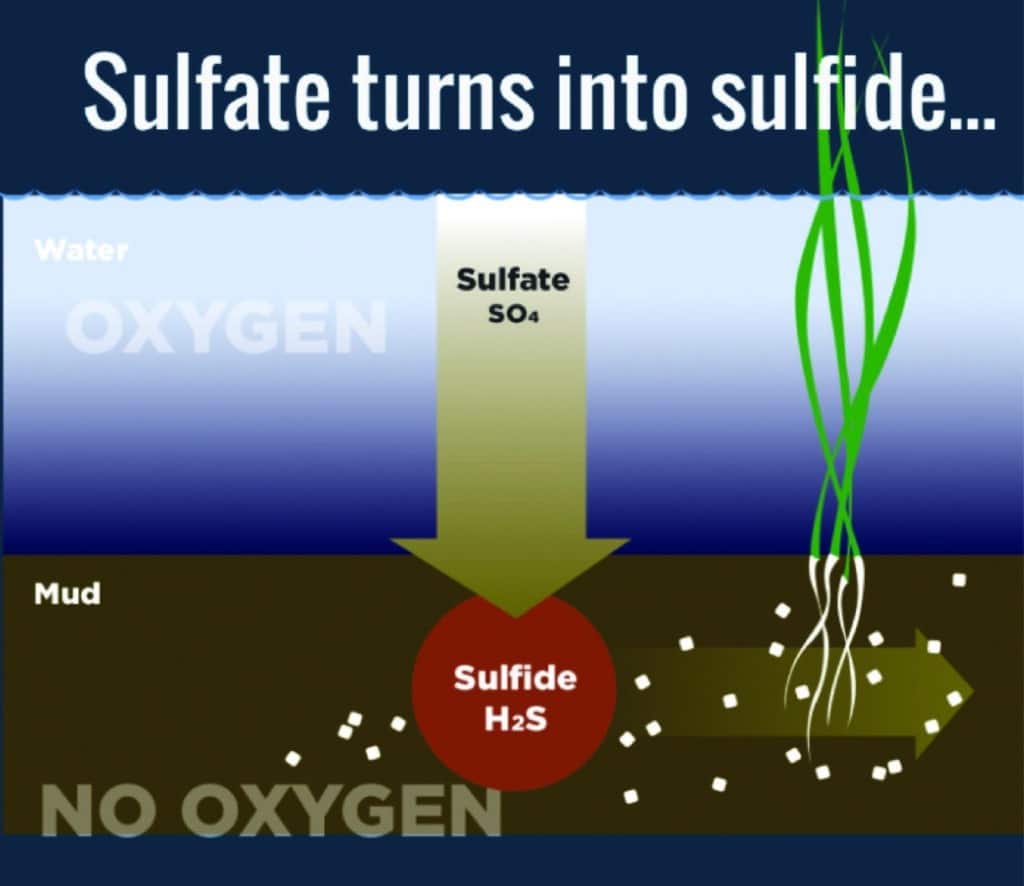

Sulfate remains active in oxygen-rich environments. It migrates into sediment and mud, where microbes consume the available oxygen. Sulfate-reducing bacteria then take over, stripping oxygen from the sulfate so they can breathe. They continue consuming biomass, and this biological process produces hydrogen sulfide, the rotten egg smell most people recognize. Hydrogen sulfide is toxic to both humans and wild rice.

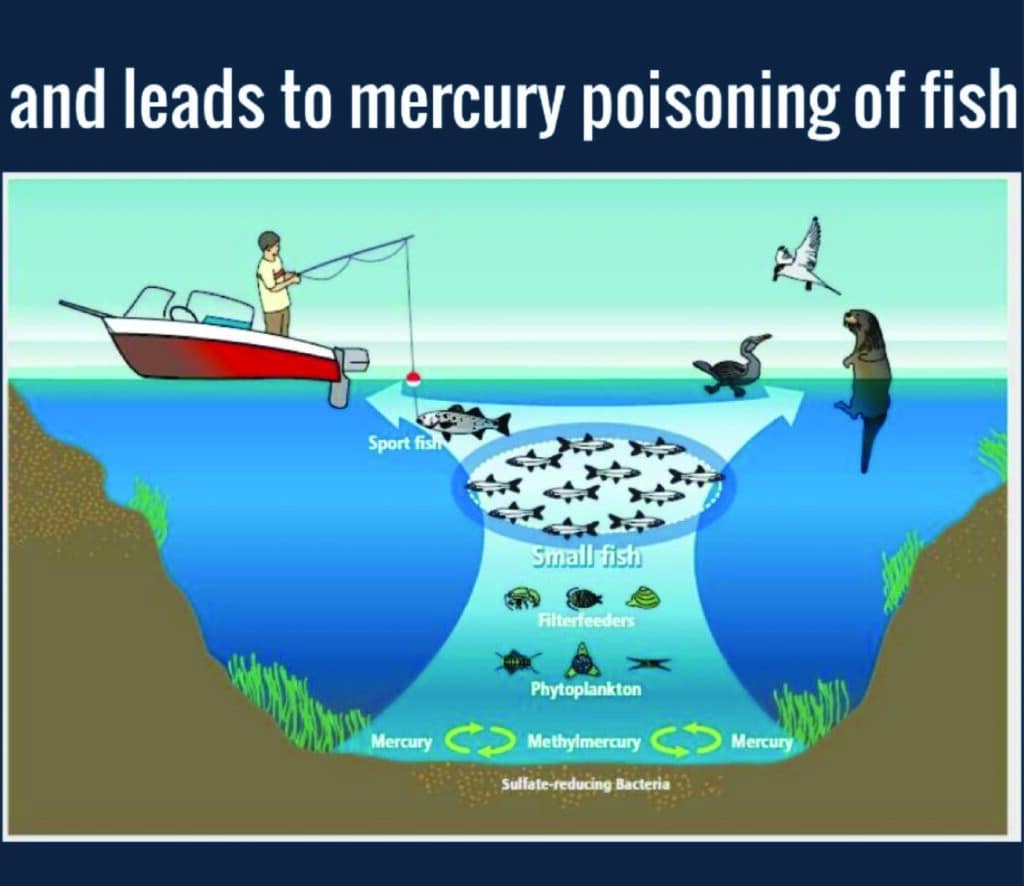

Another concern is mercury. As bacteria break down biomass, they release built-up mercury. This mercury transforms into methylmercury, which dissolves in both water and fat. It enters the food chain and accumulates in fish, leading to unsafe mercury levels in game fish consumed by humans.

Tribes say sulfate is impacting wild rice growth

Wild rice has long been a staple for native tribes in northern Minnesota. Harvest typically occurs from mid-August through the end of September. In 1973, Minnesota established a strict sulfate standard of 10 milligrams per liter to protect wild rice. However, many lakes that once supported thriving wild rice now exceed that standard.

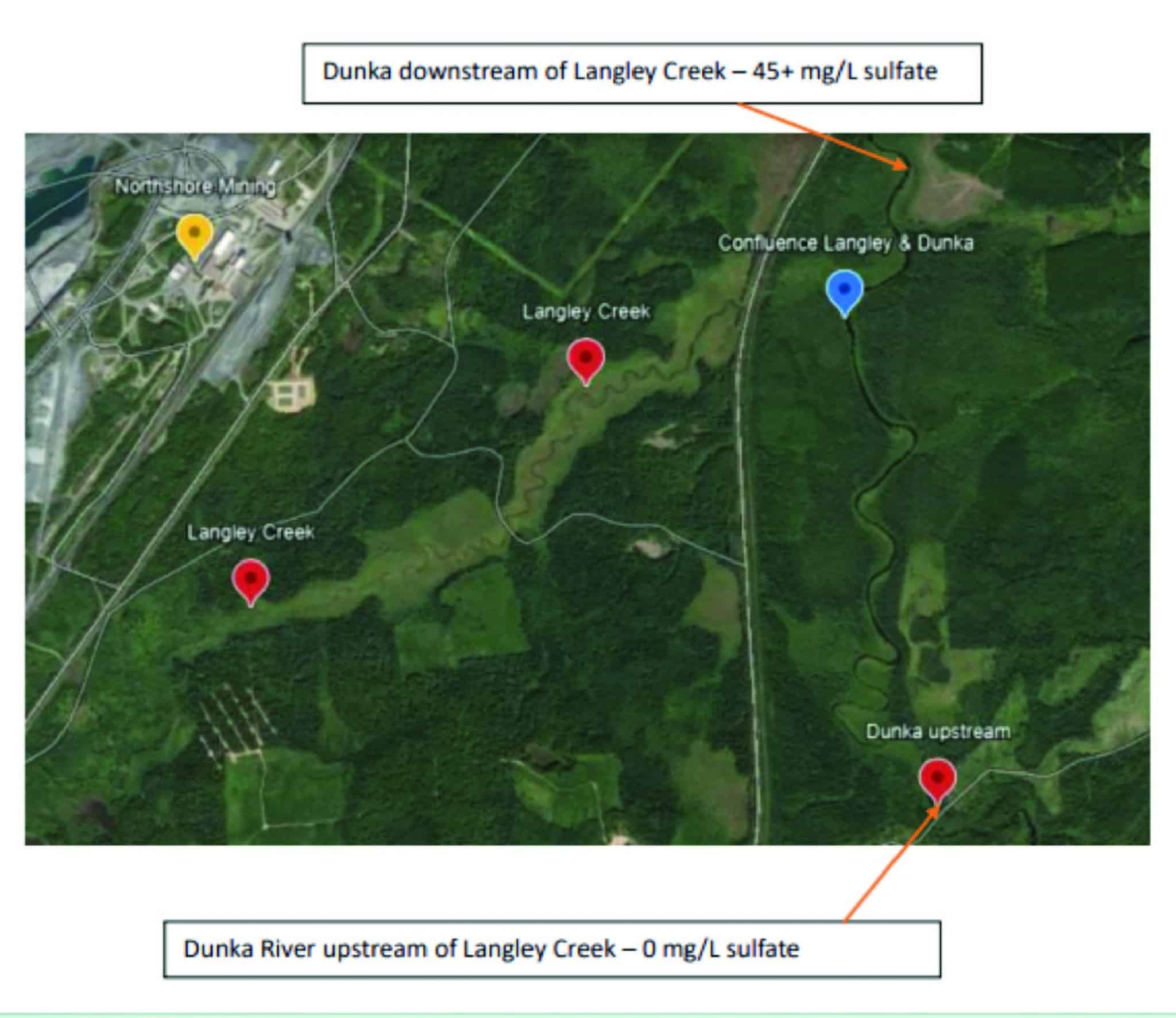

Birch Lake is one of several northern lakes listed as impaired due to high sulfate levels. Scientists from the Northern Lakes Scientific Advisory Panel (NLSAP) identified the Dunka River as a source of the sulfates. The river outlets on the southeastern shore of Birch Lake. Eric Morrison, who holds a PhD in chemistry, said mine waste from the Northshore taconite mine flows into Langley Creek and shows high sulfate levels near the source, where the mine discharges wastewater into the creek. Langley Creek connects to the Dunka River, which eventually flows into Birch Lake. This leads to a rise in mercury in fish, which is harmful to humans, especially pregnant women and children.

Other developments for removal

The Natural Resources Research Institute (NRRI) at the University of Minnesota is also actively developing technologies to remove sulfates. They explain that sulfates enter lakes and groundwater through various pathways. In response, they are creating three targeted solutions: one for municipalities, one for industries (including mine pits), and one for site-specific, sulfate-related water treatment challenges.

“Sulfate concentrations vary widely across the state from a variety of sources. But if we customize our approach, we can be most effective for each situation,” said Project Lead Chan Lan Chun, NRRI environmental engineer.

Since then, they have continued testing their sulfate technology using mobile trailers at different industrial and municipal sites in northern Minnesota. They also hope to establish a commercial partnership to implement their reduction system.

Objectives to treat at mine site

Recently, the White Iron Chain of Lakes Association (WICOLA), a nonprofit that includes Hanson as a member, submitted a grant request to the Legislative-Citizen Commission on Minnesota Resources (LCCMR). The commission is made up of politicians and citizens who recommend funding for special environmental and natural resource projects to the state legislature.

They are seeking $727,000 to demonstrate the sulfate reduction system at a taconite mine site. The team plans to show that the mobile bioreactor system can reduce sulfate pollution in a tailings pond and do it cost-effectively. The team will station the mobile trailer along the Dunka River and hopes to place the mobile bioreactors at a mining site during the year-long project. Hanson says third parties will have access to the lab, including Tribes, mining interests, environmentalists, scientists, researchers, and school groups.

The treatment plan includes remediating discharge water from Dunka Pit Lake and treating sump water from Northshore Mine. Clearwater BioLogic and Bay West, a Minnesota-based environmental planning and remediation company, will be subcontractors to WICOLA, which is the lead on the LCCMR project.

Clear concerns

While Clearwater BioLogic’s pilot projects show strong potential, some tribal leaders and environmental advocates urge caution. They emphasize that new technologies must be independently verified, transparent in their results, and closely monitored to prevent unintended consequences. For example, hydrogen sulfide — an intermediate step in the process — is itself toxic, and questions remain about the long-term stability of iron sulfide byproducts. “High sulfate discharges to wild rice waters, which in this part of the state are naturally very low in sulfate, have decimated wild rice stands that receive those discharges,” said Nancy Schuldt, water resources specialist for the Fond du Lac Band of Lake Superior Chippewa. “These are wild rice beds which, a generation ago, were actively being harvested by tribal and non-tribal harvesters. Sulfate doesn’t kill wild rice instantly or directly; it is a cumulative effect over multiple growing seasons.” (WDIO Mining News)

Advocates also stress that cleanup technologies should complement, not replace, strong enforcement of Minnesota’s 10 milligrams per liter sulfate standard for wild rice waters.

More info:

- Meeting the Need: Sulfate Solutions – Following Nature’s Lead – Clearwater BioLogic

- Protecting wild rice waters – Minnesota Pollution Control Agency

- Sulfate release and transport from taconite tailings basins – Minnesota Department of Natural Resources

- Sulfate multi-discharger variance- Minnesota Pollution Control Agency

- Fish Consumption Guidance Updates for Some Waterbodies in 10 Minnesota Counties – Minnesota Department of Health